In-Mold Decorations: Integrating Style and Manufacturing Excellence

In-Mold Decorations: Integrating Style and Manufacturing Excellence

Blog Article

In-Mold Decorations Demystified: Opening the Secrets Behind This Advanced Production Refine

In today's fast-paced manufacturing landscape, in-mold designs have actually arised as a sophisticated technique that proceeds to intrigue sector specialists. This cutting-edge manufacturing process holds the pledge of changing the means we perceive and utilize attractive components in numerous items. As we explore the complexities of in-mold designs, a world of cutting-edge possibilities unfolds, using a glance right into a world where layout fulfills functionality in a seamless fusion. In-Mold Decorations. Stay tuned as we dissect the underlying principles and unveil the enigmatic allure of in-mold decorations, clarifying the secrets that push this procedure to the leading edge of contemporary manufacturing methods.

The Advancement of In-Mold Decorations

The advancement of in-mold decors has been noted by significant developments in technology and style development. In-mold decors were limited in their intricacy and color options. However, with the advent of brand-new manufacturing techniques and products, the possibilities have actually broadened exponentially.

One secret advancement has actually been the development of high-resolution printing procedures that enable complex designs with lively colors to be moved onto products throughout the molding procedure. This has enabled suppliers to accomplish photorealistic photos and comprehensive graphics that were formerly unattainable.

Furthermore, the combination of robotics and automation in the in-mold decoration process has actually improved effectiveness and uniformity in applying designs to items. This not just decreases manufacturing time yet also improves the total quality of the completed items.

Understanding the In-Mold Process

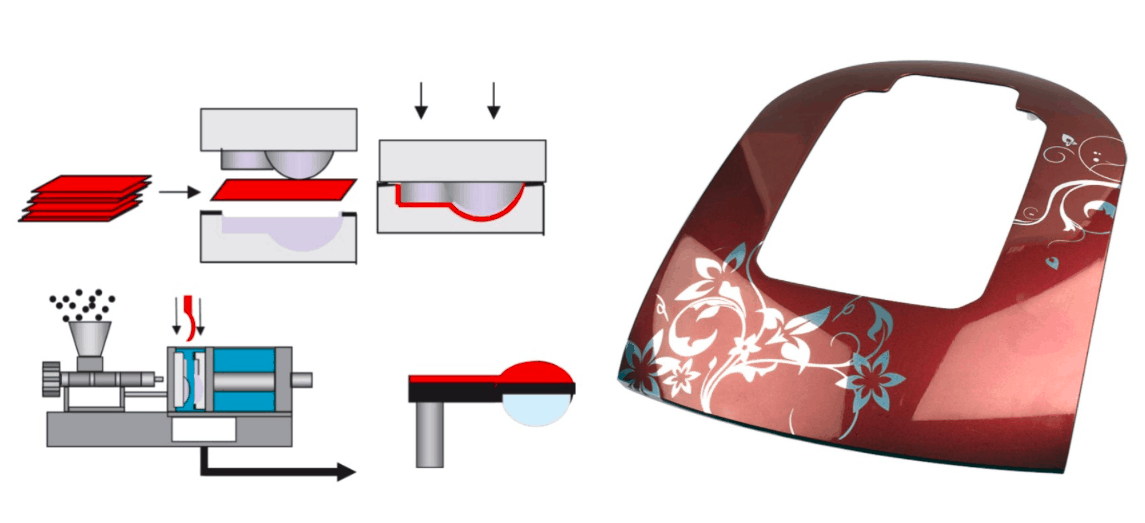

Marked by substantial improvements in modern technology and layout innovation, the evolution of in-mold decors has paved the method for a deeper understanding of the elaborate process involved in creating these decorative components. The in-mold procedure is an innovative production method where decorative elements are incorporated straight right into the final product throughout the molding procedure.

Understanding the in-mold procedure needs accurate control over various criteria, consisting of temperature, stress, and timing, to ensure the decor adheres properly to the item. Additionally, picking the ideal materials is critical to accomplishing premium outcomes. By grasping the intricacies of the in-mold procedure, producers can generate visually striking items with resilient, long-lasting designs that enhance both the looks and capability of the end product.

Benefits of In-Mold Decorations

Progressing product looks and sturdiness, in-mold decors provide a structured method to incorporating decorative aspects throughout the manufacturing process. Among the learn this here now key benefits of in-mold decors is the seamless combination of structures, shades, and graphics directly into the product throughout the molding procedure. In-Mold Decorations. This eliminates the requirement for post-production design approaches, such as painting or printing, which can be pricey and taxing

Furthermore, in-mold designs are extremely sturdy as the graphics are enveloped within the product, making them resistant to wear, scratches, and fading. This leads to items that keep their aesthetic allure and branding for a longer duration, also in harsh atmospheres.

Along with improving appearances and resilience, in-mold designs likewise use raised layout adaptability. Manufacturers can easily incorporate intricate designs, textures, and branding elements that would be challenging or impossible to accomplish with typical design techniques.

Applications Throughout Industries

Across different sectors, in-mold decorations have located versatile applications that improve both the aesthetic allure and resilience of items. In addition, the appliance market uses in-mold decors to create durable and stylish control panels and fascia for products like stoves and fridges. Generally, in-mold decors offer a affordable and effective means to Recommended Site enhance the visual appeals and toughness of items throughout a vast variety of markets.

Future Patterns in In-Mold Technology

The evolution of in-mold decors is poised to proceed forming the landscape of product design and manufacturing as Future Trends in In-Mold Modern technology assure innovative services to additionally boost aesthetic aesthetic appeals and product toughness. Among the vital future trends in in-mold technology is the advancement of sophisticated materials that use boosted toughness and adaptability, enabling even more intricate and complex designs to be realized. Additionally, advancements in digital printing techniques are enabling manufacturers to achieve better customization and detail in in-mold decors, opening brand-new possibilities for innovative product designs. An additional substantial fad is the combination of wise innovations, such as NFC tags or LED lighting, straight right into in-mold designs, adding functional and interactive components to items. Additionally, the adoption of eco-friendly products and processes in in-mold technology is coming to be significantly crucial, as sustainability continues to be a driving pressure in the production industry. In general, the future of in-mold modern technology holds excellent prospective for pressing the limits of design opportunities and enhancing the total high quality of items across numerous markets.

Final Thought

In-mold decors have actually changed the manufacturing process by seamlessly integrating design aspects into products. With its various benefits and flexible applications across different markets, in-mold innovation is poised to continue shaping the future and developing of manufacturing.

By mastering the intricacies of the in-mold process, manufacturers can produce aesthetically striking items with sturdy, durable decors that improve both the appearances and capability of the last item.

Advancing product visual appeals and resilience, in-mold decorations offer a structured technique to incorporating decorative elements during the manufacturing procedure. One of the crucial benefits of in-mold decorations is the smooth combination of textures, graphics, and shades directly into the item during the molding procedure.The development of in-mold decorations is positioned to continue forming the landscape of product layout and production as Future Trends in In-Mold Technology assure ingenious solutions to additionally enhance aesthetic looks and product longevity.In-mold designs have actually transformed the production process by flawlessly integrating layout aspects right into Continue products.

Report this page